Engineering. Design. Production.

Streamline your projects from start to finish at our all-inclusive engineering facility, handling every phase in-house from design and manufacturing to final testing.

15,000 Square Feet

20' Ceiling Clearance

Full Size Drive-in Bay

1 Ton Crane

Material Handling

Our material handling systems, which include a 1-ton overhead crane and a forklift, efficiently move raw materials, work-in-process, and finished goods through our production facility.

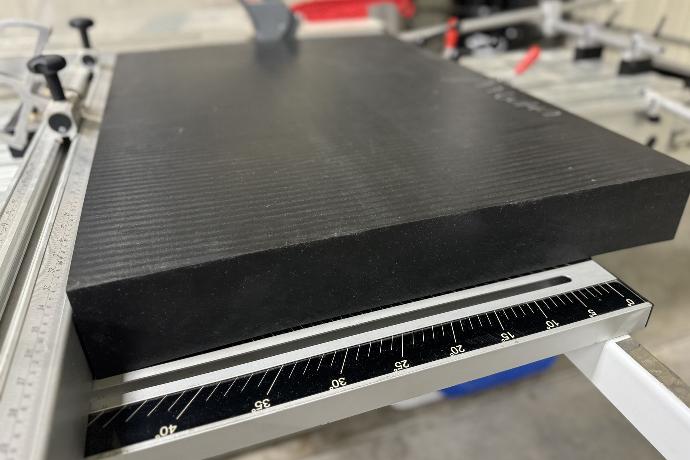

CNC Machining

Our CNC machining area is equipped with three Haas machines that provide precision part production to tight tolerances.

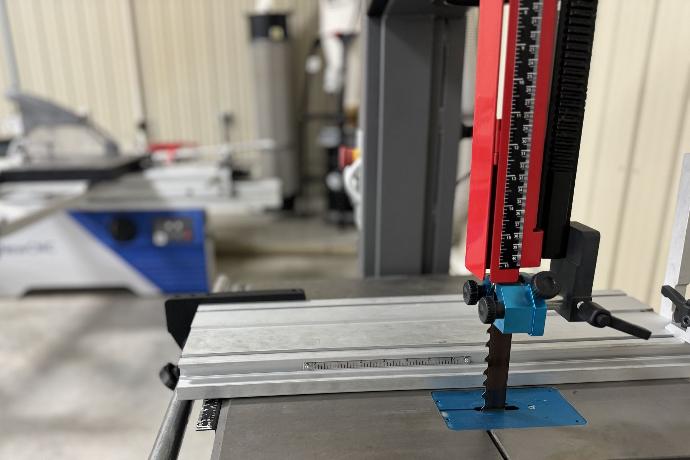

Lasering

Our laser engraving station precisely marks all of our products with critical identifying information such as part numbers, program names, and unique serial numbers.

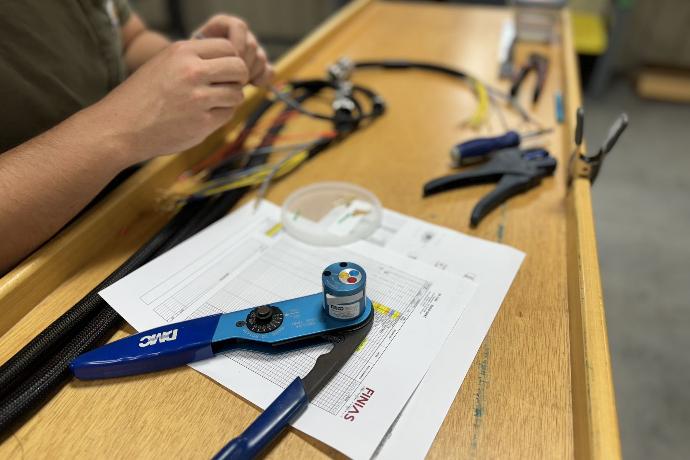

Assembly

Our assembly area is equipped with wire-pulling tables, arbor presses, and soldering stations to facilitate the precise assembly and integration of our products.

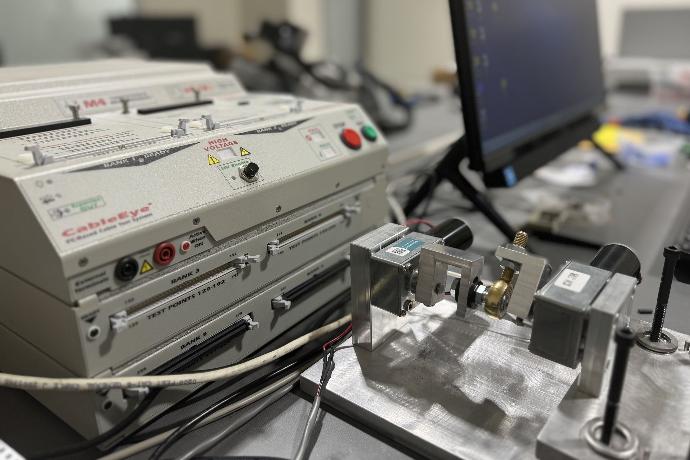

High-Voltage Cable & Harness Testing

Our high-voltage cable and harness testing area includes a CAMI system to conduct robust electrical performance evaluations of our products.

Hipot Testing

Our hipot tester measures the electrical insulation level of each device or assembly to ensure the safety and reliability of our products when operated at high voltages.