CONNECTOR PRODUCT LINE

At Finias, we proudly design, machine, and assemble a wide range of production test connectors right here in the USA. Our extensive product line spans from simple 2-pin to complex 72-pin configurations, catering to both low voltage and high voltage applications. We offer manual, robotic, and palletized solutions to suit various operational needs. Each connector is engineered for efficiency, reliability, and easy maintenance.

Whether you require a standard solution or a custom design, our American-made connectors adapt to diverse industry requirements and testing environments. Choose Finias for connectors that combine versatility with dependable performance, backed by our unwavering commitment to quality and innovation.

Rigorous Quality Assurance

Our dedication to quality is evident in our rigorous inspection process, with meticulous checks performed at each stage of production.

Precision Fit Verified

We validate component fitment against customer-supplied samples, ensuring precise compatibility.

Robust Continuity Verified

Our connectors undergo rigorous testing for pinout accuracy and continuous reliability under simulated real-world conditions.

High-Voltage Safety Verified

We subject all applicable connectors to high-potential testing, ensuring zero electrical leakage for optimal safety.

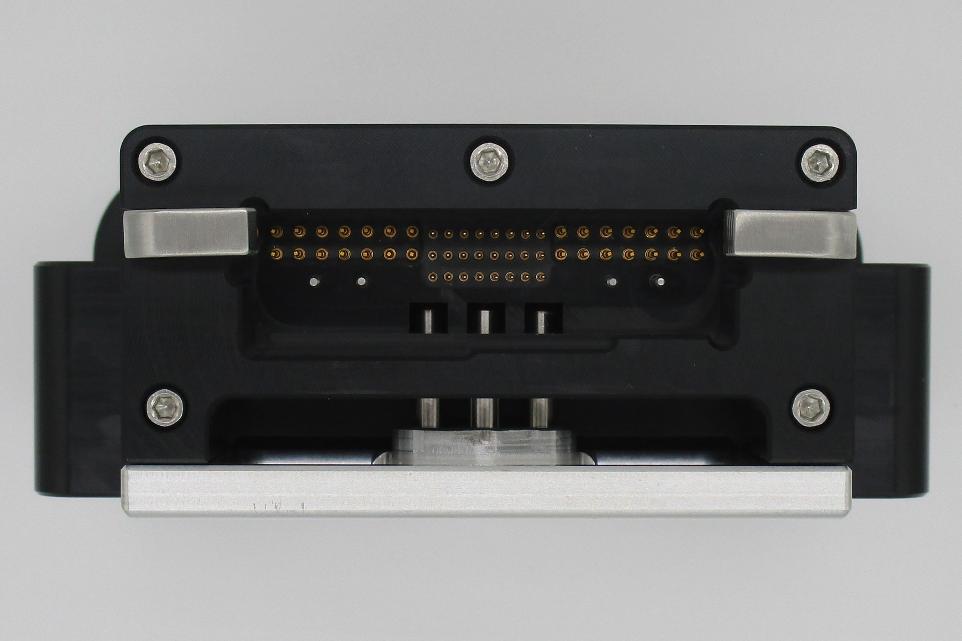

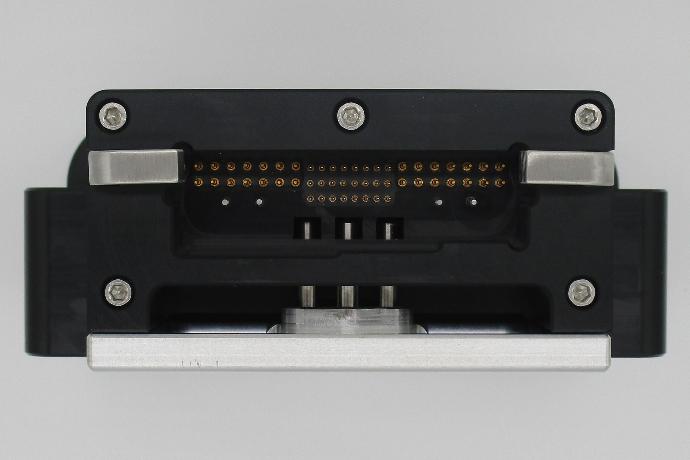

High-Voltage Application Connectors

Our high-voltage application connectors are engineered to meet the most demanding requirements of elevated electrical potential environments. These connectors are built with premium insulation materials and incorporate advanced design features to prevent arcing and ensure safe, reliable performance at high voltages. Each connector undergoes rigorous testing, including dielectric strength verification and partial discharge analysis, to guarantee its integrity under extreme electrical stress. The pin layout and spacing are optimized to maintain proper clearance, enhancing safety and longevity.

Trusted by Industry Leaders in Automation

We are in good company.

We Can Design a Custom Solution for You

Ready to create tomorrow's solution today? Click the 'Request a Quote' button to get started!